Outcome-based ERP Implementations for Midsize Manufacturers

Ivan Rebolledo

Chief Revenue Officer at TCP

Outcome-based is not cool technology, nice color graphics, or a barrage of functionality offered by outsized vendors trying to come down market. and that in most cases is never used. That’s why your ERP project is never solely an IT project.

What we have observed over more than two decades on ERP implementations for midsize manufacturers is that the way companies evaluate their ERP investment is a very good predictor of how they will perform them during the implementation.

In the realm of midsize manufacturers and distributors, certain metrics or objectives that have been known and understood for decades by internal evaluation leaders and external selection consultants, yet rarely make it into RFPs and evaluation processes, and for the most part are rarely used by decision makers to define the best system or the best partner.

It is then very common that ERP selections focus primarily on feature-function and technical capabilities, losing sight of how the different solutions achieve the desired business benefits. This is in part because many midsize companies have limited experience with technology projects and tend to rely on IT. In many cases, a few vocal users and managers with very specific needs, rather than clearly defining the specific business objectives at C-Level, work on the necessary platform and tools from there. And again, those metrics and objectives are known and understood by most professionals and experienced executives and managers, there is indeed not much new under the sun. Here are some examples:

Business-Driven Goals

- OEE above 85%

- Reducing production downtime by 20%

- Improving inventory accuracy to 98%

- Shortening order-to-cash cycle by 15%

- Increasing on-time delivery to 95%

- First pass yield at 99%+

- Inventory turnover ratio 5-10

- Development of 95% on-time delivery

- 25%+ reduction of cycle time

- Best in class customer satisfaction

- Perfect order rate of 95%+

Ultimately, all these goals have an impact on the larger objectives of increased sales, cost reduction, and improved profitability.

The thesis is that prioritizing strategic goals and developing the necessary functional and technical capabilities to achieve those goals is a more effective approach to achieving the desired outcomes. Clearly, each business has its own priorities and challenges, and understanding those is the first step in planning a tailored business transformation.

Since most midsize manufacturers and distributors lack the time and specialized human resources required to map out objectives vs. capabilities, they tend to hire external help in the form of evaluation consultants. Which is, of course, a logical course of action. Yet in most cases, the consultants adhere to the same practices of focusing on features and functions complemented by technical support resources, vendor viability, industry expertise, etc., which are all valid attributes. The problem then is how those attributes are evaluated in the context of achieving desired business outcomes and not in the one-to-one comparison of general capabilities between possible vendors, even if these are related to specific areas of interest like: planning, scheduling, engineering, forecasting, quality control, finance, etc. or horizontal criteria like ease of use, implementation time, TCO, and others.

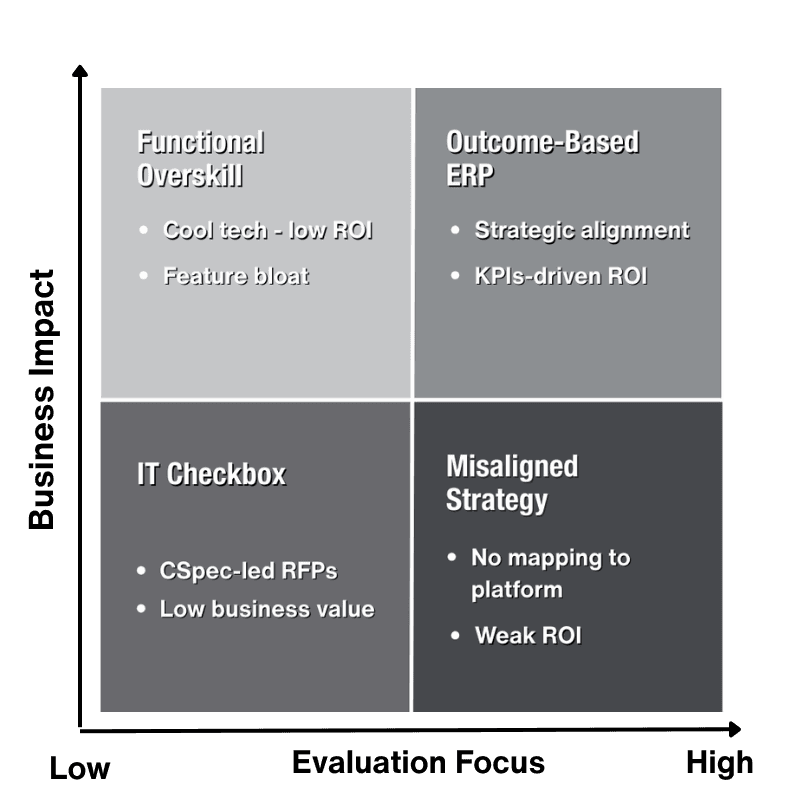

ERP Selection Approaches for Midsize Manufacturers: Function vs. Outcome

1. Functional Overskill

(Top-Left: High Business Impact, Low Evaluation Focus)

Traits:

- Projects that end up delivering value, but not because of a thoughtful selection process.

- Vendors selected due to flashy demos, excessive functionality, or technical “wow” factor.

- Companies often spend significantly more time and money than necessary.

- High post-go-live cost due to underutilized features and customizations.

Risks:

- Feature bloat leads to user confusion.

- Poor alignment between the tools used and the metrics that actually matter.

- Long implementation cycles.

- Often driven by: IT departments, over-engineered RFPs, or consultants focusing on completeness over relevance.

2. IT Checkbox

(Bottom-Left: Low Business Impact, Low Evaluation Focus)

Traits:

- ERP selected based on standard checklists or "good enough" vendor scores.

- RFPs are spec-driven, focused on infrastructure, general functionality, or vendor reputation.

- Little or no input from C-Level on strategic business goals.

Risks:

- Implementation may succeed technically but fail to move key business metrics.

- System adoption is weak because users don’t see the connection to performance.

- ROI is uncertain or negligible.

- Often driven by: Budget constraints, lack of ERP experience, or urgency to replace a legacy system without strategic planning.

3. Misaligned Strategy

(Bottom-Right: Low Business Impact, High Evaluation Focus)

Traits:

- Leadership defines meaningful strategic goals (e.g., reduce cycle time, increase delivery performance), but these are not properly translated into the system selection process.

- Vendors pitch high-level alignment, but teams evaluate based on functions again.

- System lacks the configuration or data model to support actual KPIs.

Risks:

- Disappointment post-implementation: “It does everything, but not what we needed most.”

- Strong business goals, but wrong tools.

- Expensive to rework after go-live.

- Often driven by: Disconnect between business leadership and ERP project team, or a poor handoff between strategy and execution.

4. Outcome-based ERP

(Top-Right: High Business Impact, High Evaluation Focus)

Traits:

- The gold standard quadrant.

- Starts with clearly defined, measurable business outcomes like:

- On-time delivery >95%

- OEE >85%

- Order-to-cash cycle reduction by 15%

- ERP capabilities (planning, scheduling, inventory, quality, etc.) are evaluated in direct relation to how they support these outcomes.

Benefits:

- Clear KPIs make it easy to track progress and prove ROI.

- Tighter alignment between people, processes, and technology.

- Executive engagement is higher; adoption is stronger.

- Often driven by: Strong business leadership, collaborative cross-functional teams, and experienced ERP partners or consultants who prioritize transformation over software.

Bottom Line:

- The most costly quadrant is "Functional Overkill" — you get some benefits but pay far too much.

- The most dangerous quadrant is "IT Checkbox” it gives a false sense of progress with real results.

- "Outcome-based ERP" is where transformation lives.

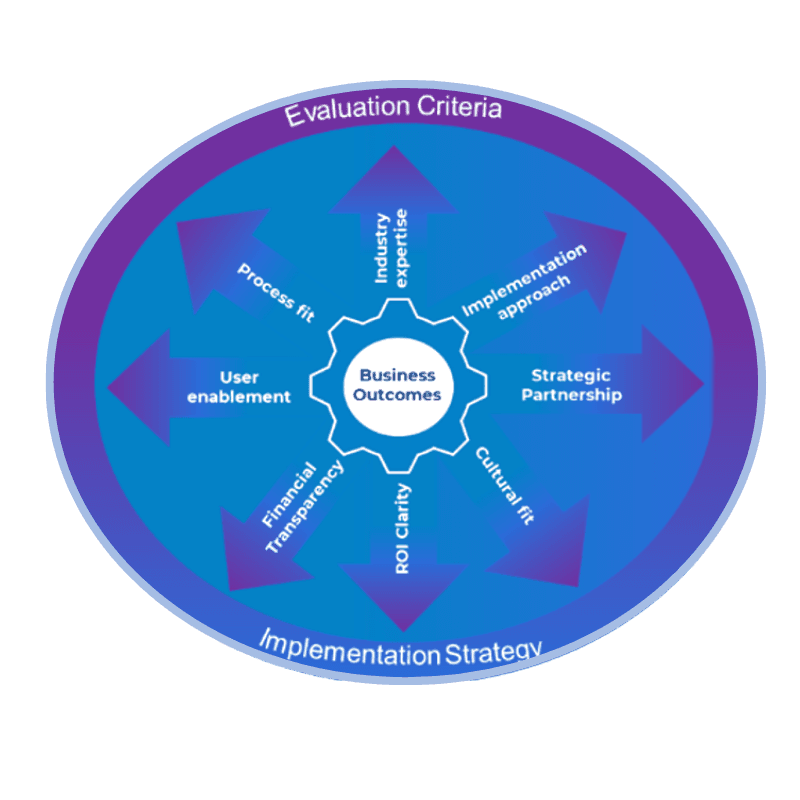

By building an evaluation process focused on business outcomes from the start, your team can calibrate the relative importance of the different solutions’ attributes and therefore spend its time researching and proving the most relevant features, functions, or technical capabilities to achieve your specific transformation goals. Eliminate unnecessary and cool but unquantifiable features and capabilities that do not align with your core needs.

And a strategically important bonus of this approach is that calculating ROI is much easier, as you probably already know or at least understand where your main challenges to get to the desired performance are. Going to your board or business owners with an outcome-based analysis will provide a clearer picture of the differences and the ways in which each vendor offers to deliver the tools and services to get there.

And keep in mind, the evaluation criteria do not change much from the traditional ways in which ERP implementations have always been analyzed. What flips the approach dramatically is to focus on business outcomes from the start and then carry that same focus into the implementation strategy, never losing sight of the most impactful performance metrics of the business.

What we have observed for more than two decades on ERP implementations for mid-size manufacturers is that the way companies evaluate their ERP investment is a very good predictor of how they will perform during the implementation. Our typical job is to help customers align their own business priorities with the processes and capabilities of the software solution. The more clarity at the leadership level of what those priorities are, the better and faster the deployments become, with very little room for failure, even if the solution design changes from the original functional and technical definitions. Which is also a reason to make sure the selected ERP has the bandwidth and flexibility to adapt without sacrificing its ability to deliver the expected results.

This typically comes from selecting the right-sized industry-specific solution. The flexibility is not limitless since that will imply a custom software development project, but it must be able to allow the customer to make changes to the business logic to fulfill very specific functional and technical requirements that are key to its optimal performance. Three of the above evaluation/implementation criteria will take care of this for you:

- Process Fit

- Industry Expertise

- Strategic Partnership

And since you are probably like any other cost-conscious, risk averse business leader on the planet, the following will help you drive and monitor progress during the project execution, and will also add visibility to anticipate issues and deviations from your project timeline and budget:

- ROI Clarity

- Financial Transparency

- Implementation Approach (methodology)

Finally, making sure your own teams adopt change and commit to success, you need a partner that aligns to your own company ways to solve day to day problems and disruptions, one that understands not only the best practices of your industry, or the requirements to operate a business like yours in your specific geography, or markets, and for that the last two elements are key, and many times forgotten or oversighted:

- Cultural Fit

- User Enablement

In conclusion, a business-outcome based ERP evaluation and implementation is the proven way to avoid the typical pitfalls and shortcomings of transformation projects for midsize companies, securing not only that your strategic objectives to invest are achieved, but that they are supported by your own team in the long run while keeping time and cost under control all along the way.