Data-Driven Transformation

A story of evolution and digital transformation with strategic vision.

In the dynamic manufacturing sector, digital transformation has gone from being a competitive advantage to a fundamental pillar for development and growth. For Alico S.A.S / BIC, a leading Colombian company with over 44 years of history in the flexible packaging industry, this materialized with the implementation of Epicor Kinetic.

About the Company

"Proudly Alico" is the corporate motto that reveals its philosophy.

Alico's headquarter and manufacturing plant in Medellin, Colombia

Alico S.A.S / BIC, founded in 1981 and headquartered in Medellín, Colombia, is a leader in the manufacture and marketing of flexible packaging. The company is distinguished by its commitment to innovation, ethics, and the well-being of its 1,500 employees, whom they consider an essential pillar of their success. With an annual production of approximately 15,000 tons of packaging, Alico serves a wide range of industries, including food, cosmetics, and pharmaceuticals. Beyond its solid market in Colombia, the company has expanded its reach to 17 countries, demonstrating its ability to compete globally.

The Challenge: An Operational Puzzle

In 2013, Alico was a growing company, but its technological infrastructure could not keep pace. They operated with a basic accounting system and a series of isolated internal developments that worked through Excel macros. This fragmented method created critical inefficiencies:

- Lack of integration: Different departments operated in silos, with disconnected processes that hindered coordination and information flow.

- Fragmented information: It was nearly impossible to get a unified and accurate view of the operation. The lack of real-time data prevented agile and well-informed decision-making.

- Unmanageable data volume: Manually managing a large volume of monthly production orders was a logistical challenge that saturated the network and limited productivity.

Elías Jaramillo describes it as a "technological backwardness" that made "it impossible to operate that way anymore." The company needed a comprehensive solution that would lay the foundation for its future expansion.

"Today, it is very difficult for any company to understand its business if it does not have a robust technology platform that allows it to manage data properly. This is even more critical in an organization like ours, which processes around 1,600 work orders per month in its production plants. We are highly demanding in terms of information processing because we handle a very high volume of data that requires accuracy, timeliness, and traceability."

Elías Jaramillo - Supply Chain Director - Alico S.A.S / BIC

The Solution: Epicor as the Backbone

After an exhaustive selection process that included all world-class ERPs, Alico chose Epicor Kinetic with the support of Technology Coast Partners (TCP). The decision was based on three pillars:

- Requirements coverage: Epicor offered exceptional coverage of 87% of Alico's needs, the highest among all the solutions evaluated. This meant that the technology solution could handle almost all of Alico's complex manufacturing processes natively.

- Flexibility and adaptability: Unlike more rigid solutions that required "doing things one way," Epicor presented itself as a "user-friendly" and "much less restrictive" system. This flexibility was vital for a family-owned company entering the world of ERP for the first time. It allowed them to tailor the system to their specific needs without having to radically change their internal processes.

- Technology and economic competitiveness: Epicor stood out for its modern architecture and highly competitive price, making it the most comprehensive and accessible package for a Latin American company.

The full implementation integrated all stages of Alico's production process, from sales orders to production, supply chain and final distribution.

"This is not a back office, simply accounting. This is where the entire manufacturing process of a company that today, this year, will be billing just over $110 million operates."

Elías Jaramillo - Supply Chain Director - Alico S.A.S | BIC

Tangible Benefits: Data-Driven Growth

The adoption of Epicor Kinetic transformed Alico's operations, generating measurable results and exponential growth:

- Informed decision-making: Epicor Kinetic provided Alico with the accurate and reliable information it needed to optimize its business. Elías Jaramillo sums it up: "The volume of information that ERP provides us is enormous, and we owe this progress to ERP."

- Drastic reduction in inventory: With only 18 months of information in the system, Alico was able to develop a statistical model that allowed them to reduce their inventory levels by 50% without compromising operations. This freed up working capital and improved supply chain efficiency.

- Growth and scalability: Epicor Kinetic has been the cornerstone of the company's remarkable growth, which has quadrupled its production volume since 2015. It has proven to be a platform robust enough to scale with business demand, which has grown at a rate of doubling every 5-6 years.

- Long-term investment planning: Epicor Kinetic's analytical capabilities enable Alico to make investment decisions 1 to 2 years in advance. The system helps predict when production plants will reach 85% capacity, allowing the company to purchase high-productivity machinery (with purchase cycles of one year or more) at the right time to maintain growth without exceeding capacity. This is crucial for a $25 million investment plan over the next three years.

Alico's Distribution Center in its Medellin, Colombia installations, from 2,000 m² to 9,000 m² today

Elias Jaramillo recounts how, by quadrupling its production volume, Alico has had to expand its Distribution Center from 2,000 m² to 9,000 m² today, where raw materials are received and the entire distribution process for the finished product is carried out. He emphasizes that: "If sales double, the size of the plants will also double, and in five years those 9,000 m² will be completely absorbed by the manufacturing process, and the Distribution Center will have to move to another location. And as I said, all of this has been done through Epicor, with the same infrastructure we have available."

The Competitive Advantage: Skills and Specialization

Alico not only competes efficiently, but also with a unique value proposition for its clients backed by technology. While large multinationals focus on mass customers, Alico specializes in serving a Latin American market with small and medium-sized companies that require barrier packaging in small quantities. Epicor Kinetic's flexibility allows them to manage the complexity of having to perform "dozens of jobs per day per machine."

Production Order Sequencing: A Challenge and a Critical Advantage

The ability to sequence production orders is crucial for a company like Alico, which handles a high volume of small-batch jobs for a very diverse customer base. At its core, sequencing refers to the optimal organization of work orders on the production line. Its importance lies in how it directly impacts efficiency, productivity, and profitability.

- Efficiency and productivity - Sequencing minimizes machine setup or preparation time. By grouping jobs with similar characteristics (such as material type, colors, or dimensions), it reduces the number of tool changes or adjustments required, resulting in less machine-downtime.

- Bottleneck management - An advanced sequencing algorithm allows you to proactively identify and manage production bottlenecks. By intelligently redistributing workloads, the system ensures a constant production flow, preventing one machine or process from becoming overloaded while others are idle.

- Profitability - Reduced downtime and optimized use of production resources directly translate into increased profitability. For a company that must compete with large multinationals, the ability to produce efficiently and at low cost is a key competitive advantage.

- Delivery compliance - Accurate planning ensures that critical orders are prioritized and completed on time. This is vital to maintaining customer satisfaction and the company's reputation.

A Unique Challenge for Alico

For Alico, this capability is especially critical due to its business model. Unlike large companies that manufacture high quantities of a single product for a single customer, Alico must handle dozens of jobs per day per machine for thousands of customers in 17 countries. This requires extremely precise and rapid movement and adaptation capabilities.

Elías Jaramillo compares this process to the sophisticated algorithms used by airports to sequence aircraft landings or the Waze app to manage traffic in a city. The accuracy of the ERP, which receives real-time data from each machine, is the basis that feeds this specialized sequencing algorithm.

Although the Epicor Kinetic system does not directly handle sequencing, as it is a highly specialized external heuristic programming algorithm that was developed under the guidance of professors in the United States and in collaboration with Colombian universities, Epicor Kinetic is the heart that feeds this algorithm with accurate, real-time data. The information from the ERP, such as material availability, machine capacity, and the status of each order, is what allows the sequencing algorithm to function effectively, ensuring that assembly times are fast and production processes are smooth and profitable.

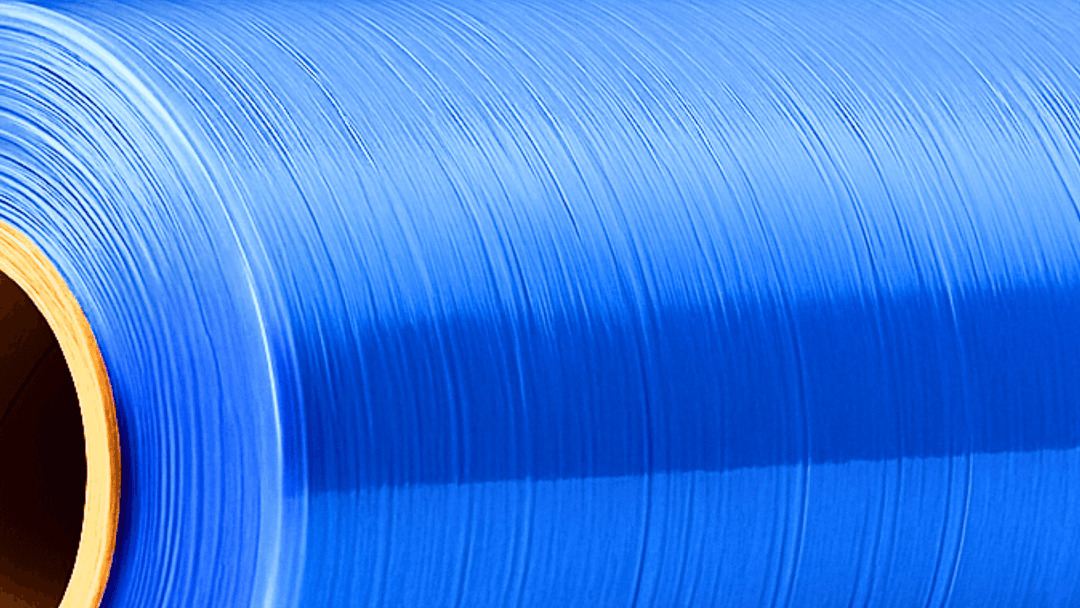

One of Alico's production areas in its Medellin, Colombia, facilities

Future Challenges and the Role of AI

Looking ahead, Alico is preparing for the next wave of innovation: Artificial Intelligence (AI). They recognize that AI will simplify processes, especially in repetitive and systematic tasks such as logistics and data analysis. The company is already training its staff to use AI and predictive analytics tools, which will allow data specialists to focus on decision-making rather than "information cleansing." AI will enable:

- Process automation: Programming "bots" for tasks such as generating shipping guides or managing inventory, freeing employees from physical and repetitive work.

- Advanced predictive analytics: The use AI algorithms to analyze large volumes of ERP data, identifying trends and potential problems for proactive intervention.

- Market prospecting: To analyze market trends, identify new opportunities, and guide the company's expansion strategy for markets such as Argentina, Chile, and Mexico.

Outcome

A testament to the transformative power of well-applied technology

The case of Alico S.A.S | BIC is powerful proof of how digital transformation and the implementation of a robust ERP such as Epicor Kinetic can be catalysts for explosive and sustained growth. By moving from a fragmented system to an integrated platform, the company not only resolved its operational inefficiencies, but also gained the visibility, flexibility, and analytical capabilities necessary to make bold strategic decisions.

Epicor Kinetic ERP not only solved the challenges of a fragmented system, but also became the foundation that enabled Alico to optimize complex processes, such as production order sequencing, which is vital to its business model.

Epicor Kinetic has become more than just software; it is the fundamental infrastructure that has enabled Alico to double in size over the last ten years and will continue to drive its growth and competitiveness in the decades to come.

The key to success: implementing ERP solutions that speak our language

Implementing a world-class technology solution is a challenge, especially for medium-sized industries in Latin America. "And I speak from experience," says Elías Jaramillo, "that the biggest obstacle is not the technology itself, but the cultural and operational barrier."

For an industrial company in our region, finding consultants who are fluent in English and also understand the complexities of our business is an almost impossible task. Professionals with these skills are scarce and expensive, and their day-to-day work does not focus on the particularities of the local industry. Working with consultants from the United States becomes a constant challenge of communication and understanding.

This is where "tropicalized" support makes the difference. Having a team that not only speaks our language but also understands the idiosyncrasies of our culture and the reality of our operations is essential. We are talking about a deep understanding of our complex labor and tax regulations, which in countries such as Colombia or Peru is a real challenge.

"Without a partner that understands and customizes the solution for the local market, world-class ERPs would be out of reach for most medium-sized companies in Latin America. Practically only large multinationals could afford them. TCP, by adapting these solutions to our reality, makes them accessible and viable. They understand our unique needs, and that is vital for companies in the region to develop and compete."

Elías Jaramillo - Supply Chain Director - Alico S.A.S | BIC

The case of Alico S.A.S | BIC demonstrates how a medium-sized Colombian company with family roots and more than four decades of successful history managed to transform itself into a major regional player in the flexible packaging industry thanks to the digital transformation supported by Epicor Kinetic.

Headquarters

Medellín, Colombia

Founded

1981

Company size

1001-5000

Industry

Manufacturing